Here we have a package from David coming from Texas, David Santos and HMS minimax diesel engine tuner HDMI is badly broken on this device. Let me show you what I mean. It looks something like this. The problem is, we are unable to find a similar HDMI port in the market that we can replace this with. I communicated with David, and I told him that we are not able to get a similar HDMI port and David looked on eBay and he was able to find a similar tuner.

Here we have a package from David coming from Texas, David Santos and HMS minimax diesel engine tuner HDMI is badly broken on this device. Let me show you what I mean. It looks something like this. The problem is, we are unable to find a similar HDMI port in the market that we can replace this with. I communicated with David, and I told him that we are not able to get a similar HDMI port and David looked on eBay and he was able to find a similar tuner.

That’S bricked. It has a bad firmware and we bought it. So we can extract the HDMI port from the other tuner and put it on this one. So this is the one that we bought off eBay and we paid $ 100 for this. It was initially listed for $ 65 and the bid went up.

I told David that maybe we should bid $ 100 maximum for this in case somebody bids on it, and there was about five bits on this tuner and we won for $ 100. The last bid was $ 99, so we wanted buy $ 1. We only bought this, so we can extract the HDMI port from it and put it on this one. We’Re going to be using low melt solder to remove the connector once it’s removed, then we’re gon na solder it back on David’s tuner. Let’S take them apart and see what’s going on and that’s the HDMI port, the port looks in a good condition.

That’S great looks very good. Actually mint. We’Re gon na have to remove this port and we have one screw here. The screen is probably glued onto the board. No, they fix yes, yes, that’s it.

Yes, uh-huh charging port on which one which device I’m gon na, remove the LCD. So we can have access to the board and we move the HDMI port. Let’S take this one apart as well: yeah, just a minute hello. How are you, okay, okay, so we took both boards out, let’s start by removing the good HDMI port and we’re gon na be very careful with this, because we paid hundred dollars for this – don’t know device, so so we’re gon na remove this edge in my port. Without damaging any of the pins, let’s take a look at the back here.

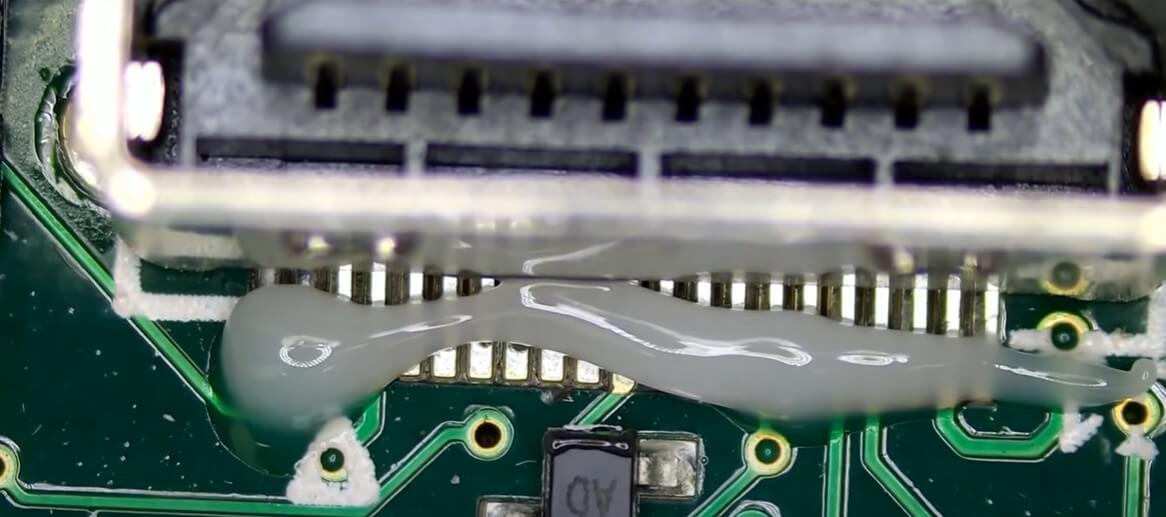

The port is soldered on, looks like it’s old enough from here. So to do this as safely as possible, we’re gon na be using low melt solder. You can apply Fox yeah, yeah, okay, so I applied flux to all three areas, all three likes of the HDMI port [ Music ]. So, as you can see, a little bit of law melts out. There goes a long way: [ Music, ], [, Music, ], we’re gon na flip.

The board now we’re gon na do the same thing to the front: pins, [, Music ], and we look at this as soon as we apply Lommel solder onto those pins they’re already loose, no just fix. Okay, almost perfect perfect. We lower down the melting temperature of unleaded solder, that’s on the board and with a little bit of heat, we were able to pry that connector off the board. I was not applying heat onto the connector, but onto the board. The board got hot, it liquefied the solder blown out solder, and I was able to safely remove that HDMI connector and look at this solder is still soft.

It stays soft for few seconds. It depends on how much heat you’re applying, but because solder stays soft on all the joints, then we can remove the whole connector at once. Now. Look at this. It’S still soft, still soft.

Let’S put it on the side and remove the port from David’s port. We’Re gon na do the same here, apply Lommel solder on to the back of the board and then we’re gon na do the same to the front. Let’S flip the board. We cannot even see those pins. It’S been to a point where we cannot even see the pins right there.

I still have Lommel solder on the tip, so we’re gon na use that to apply it after the pins. We do not care about this HDMI connector, so even if it gets damaged. That’S okay! You may be wondering why don’t we use hot air to remove this port? We do not care about this port anyway, even if it gets damaged.

While that’s true, I want to do this as safely as possible. I do not want to apply a lot of heat onto that board. It’S an expensive device. Okay, so now we use our hot air station at 350 degrees just a moment, you’re right there, okay! So let’s remove that port.

Okay, let’s go under the microscope, we’re gon na clean the pads clean the holes and solder back the HDMI connector and use a slightly bigger tipper. You talking about this flux. Look at how nicely it cleans of the board. Now we’re gon na use the HDMI port that we removed from the donor device just like that, let’s clean up some of that Lommel solder before we apply let it’s out there. Okay, that’s good enough!

I’M gon na create a fly solder on to the soldering iron tip, we’re gon na hold the connector down and start shouldering the front pins. I just want to hold this connector in place, so we can go to the back and solder the legs, so we’re gon na push down on the connector and let’s apply solder right over here and the scene. Here. You flip the board and solder. The back very nice joints are nice and shiny and we’re gon na finish off by going through those bins.

Again, I could Jen ship this back to David. We’Re gon na expect the pants to make sure everything is good. We want all depends to be solid, solid, solid and that’s all we do not have any guns here, excellent one more time. Everything is solid and the bank is already clean. Okay and the job is beautiful.

We did this as safely as possible, thanks the good folks blow melt solder, good tools and, of course, good hands. How can I forget, and that’s it for this video I’m gon na reassemble this it’s fairly easy. We connect the screen one screw and we just close the back and front casing. I hope you enjoyed this video, don’t forget to Like and subscribe leave a comment. Have any questions and we’ll do something else in the next video.